What Is Digital Twin?

The fundamental notion of a digital twin is not a new one. This model comprises the integration of virtual engineering models with actual products or equipment in a setting that allows for the modification and optimization of the product like it is manufactured. We are witnessing increasing interest in adopting the digital twin and the related benefits that may be realized as a result of progress and evolution of enabling technologies, which is good news for everyone. Let’s uncover what is digital twin and what prospects would digital twin definition mean in different industries.

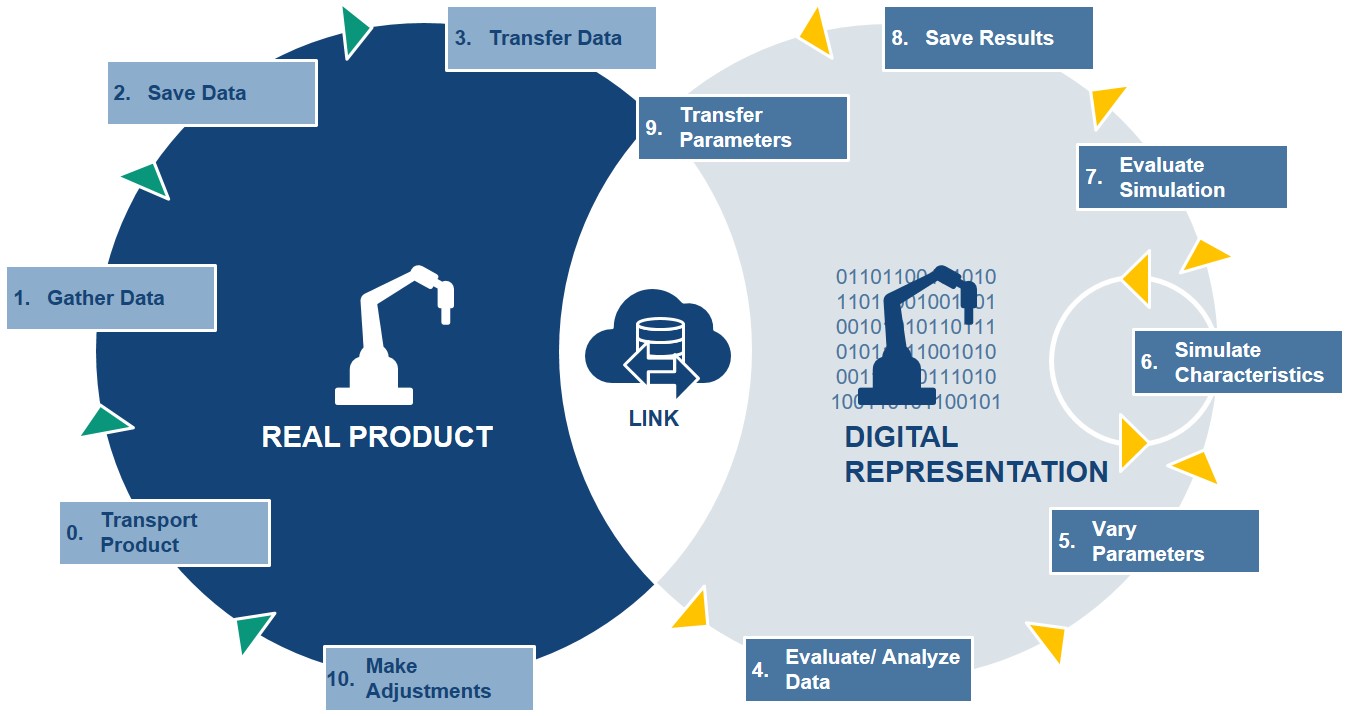

A Digital Twin is comprised of three components:

- Physical twin: A real-world entity (living/non-living) such as part/product, machine, process, organization, or human, etc.

- Digital twin: The digital representation of the physical twin with the capability to mimic/mirror its physical counterpart in real time.

- Linking mechanism: The bidirectional flow of data between the two which operates automatically in real-time. DT reduces operational costs and time, increases the productivity of the existing system, helps in the decision-making process, improves maintenance schedules and activities, provides remote access.

One of the reasons the demand for DTs has accelerated is the recent outbreak of the pandemic, COVID-19 . Lockdowns due to the pandemic resulted in supply chain breakage, a shortage of workforce, and remote or non-contact working environment , due to which digitization and the advancement of processes with minimum human contact have gained much more importance . According to the Gartner survey, 31% of the companies are using DT for the remote monitoring of assets to reduce the frequency of in-person monitoring, such as hospital patients and mining operations to increase the safety of employees and customers.